Despite the introduction of new technologies and the growing reliance on electronic transfer of information in today’s world, there is a reason that mail will certainly never go out.

There would always be the need for delivering material products from one geographical area to another, and there is no other method to perform this function besides a secure mailing system with mailing bags.

Mail is indeed not an outdated technology, however, one that has to be constantly enhanced. This is why mailing services around the world are  always looking for methods to improving their services and making the delivery system more efficient, safe and secure. The execution and enhancement of mailing services are simply not possible without mailroom products, tools and accessories that help staff of mailing services to perform their duties.

always looking for methods to improving their services and making the delivery system more efficient, safe and secure. The execution and enhancement of mailing services are simply not possible without mailroom products, tools and accessories that help staff of mailing services to perform their duties.

For those not knowledgeable about how mailing services work, their devices is supplied by devoted specialty producers. These manufacturers focus on mailing services and produce mailroom products such as mailroom tables, racks and racks and other mailing equipment such as collection boxes, mailing pouches, mail carts and handling equipment. This also includes support devices for mail sorter such as through-sort units, sort stations and sort compartment labels.

These mail items also consist of security mailing devices such as money bags, security seals, bank processing equipment, etc. Certain security equipment is manufactured with a special product such as protected money in transit smoke bags and strengthened transport bags, which help secure the important contents of the package from unexpected damage.

These mail items also consist of security mailing devices such as money bags, security seals, bank processing equipment, etc. Certain security equipment is manufactured with a special product such as protected money in transit smoke bags and strengthened transport bags, which help secure the important contents of the package from unexpected damage.

If you operate a mailing service and are concerned about the enhancement of the performance of your department, then you must focus on the quality of your mail equipment and devices. If there are problems regarding the efficiency and performance of your department and if you have been regularly encountering errors of late, then the equipment or lack of them could be an  element.

element.

A great way of boosting the efficiency and productivity of the mailing service at hand is to narrow down the problem areas, acknowledge the malfunctioning procedures and develop a solution. You would instantly come to know what tools and devices can assist you overcome the problem. Say, if your mail sorting has been often all over the place, then arranging labels might assist you keep track of things.

engineering elements of high precision.

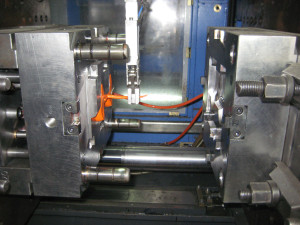

engineering elements of high precision. There are numerous business and companies who specialise in producing crucial components and products made from plastic via the process of injection moulding. There is also many companies that specialise in the production and supply of the moulds used in the injection moulding process.

There are numerous business and companies who specialise in producing crucial components and products made from plastic via the process of injection moulding. There is also many companies that specialise in the production and supply of the moulds used in the injection moulding process.